Retrofit fuel level sensor DUT-E

Highest accuracy – error 0.1%

Multiple outputs to fit your existing telematics

Stand alone, BLE and GSM capabilities

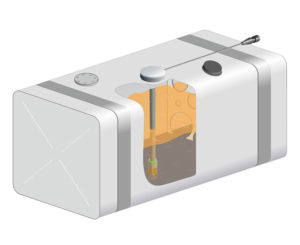

Installation to a fuel tank

For plastic and metal tanks

Installed into geometrical center of a tank

Simple installation and calibration

Constant fuel tank control

Fuel level sensor DUT-E is designed for precision fuel level measurement in all kinds of vehicle tanks, also in tanks of fixed installations. DUT-E can be used as a part of a fuel monitoring system or to substitute the standard fuel meter of a vehicle. Wide variety of output types provides seamless integration and additional data on patterns of fuel use.

Suits any diesel fuel tank

Main features

Robust design and cable – design and materials developed to prevent intrusion

Thermal correction – configurable thermal correction for automatic compensation based on ambient temperature

Self-diagnostic – digital self-diagnostics to control data reliability

Signal filtration – adjustable signal filtration to smooth the peaks for different conditions of the vehicle operation

Probe length reduction – probe length can be cut up to 70% of length

Mud filter and bottom spring – protects sensor from dirt and water in the tank

Mounting set – all necessary mounting items and cables in delivery set

Long term warranty – 5 years factory warranty

Length increase – up 6 meter length increase by using additional sections

EU Certificates – certified to comply with obligatory automobile standarts

Get a quote!

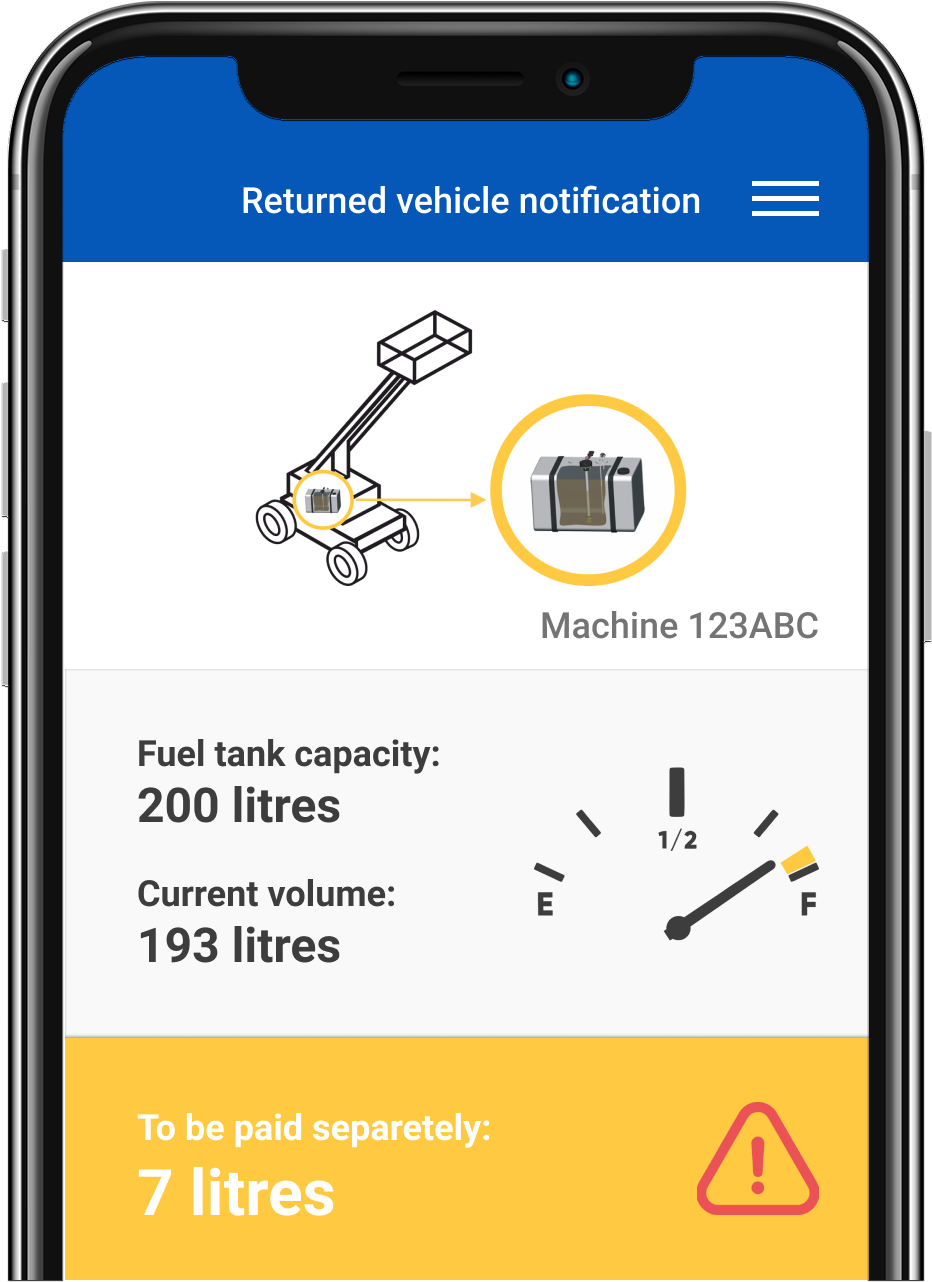

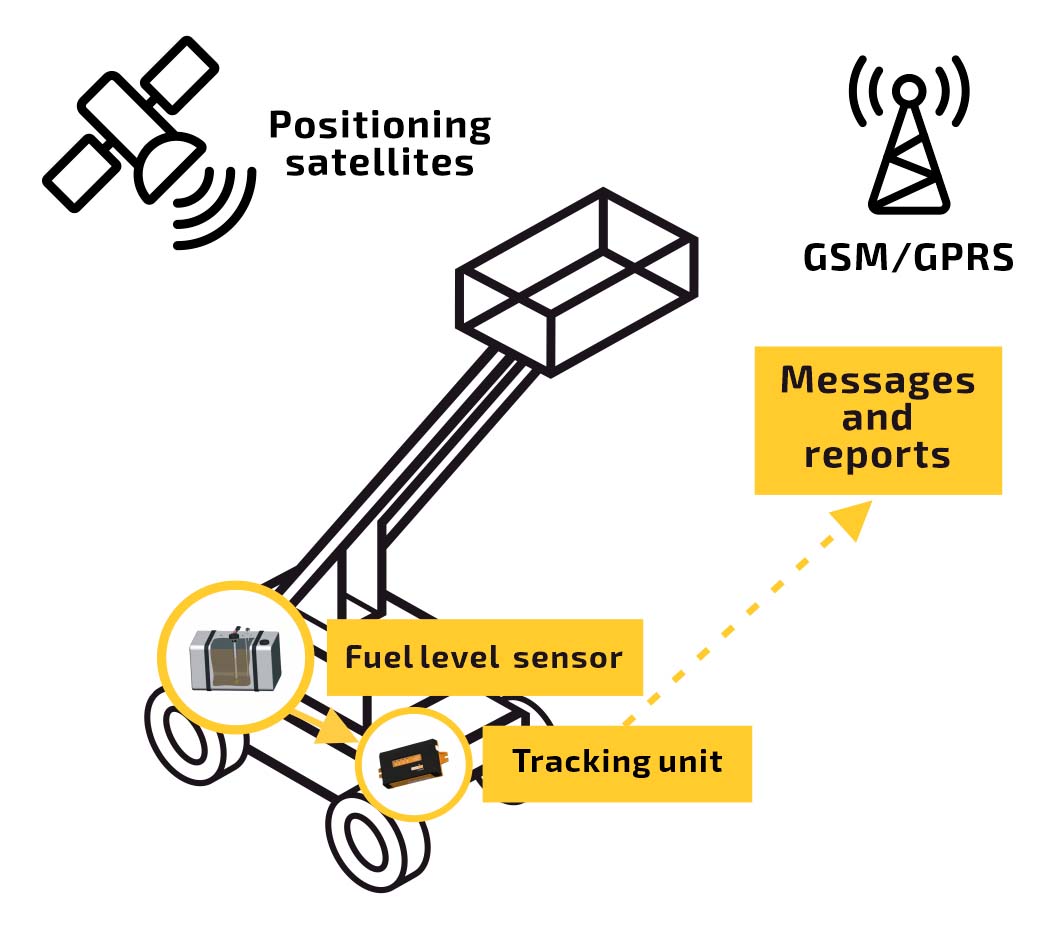

The task – on-time maintenance for rented machines

On-time maintenance is a guarantee of long and uninterrupted operation of the equipment.

Operation conditions of MEWPs – daily operating times and the number of descents/ascents – vary greatly. Therefore, it is impossible to carry out maintenance simply by the number of calendar days, that have passed since the start of lift platforms.

Main parameters that should be kept under control:

Engine running time

Engine speed

Fuel consumption and remaining fuel in the tank

Turning engine on/off

Voltage of on-board network of MEWP

The solution

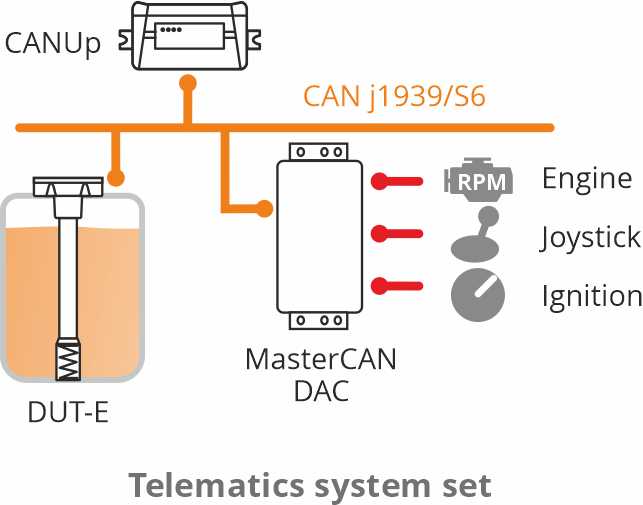

Telematics system for each vehicle is composed of:

All equipment units are connected using S6 Technology and communicating over CAN J1939/71 interface. DUT-E fuel level sensor and DFM flow meter are used for precise fuel tank monitoring and direct fuel consumption measurement, also for recording engine operation time in “idling”, “optimal” and “overload” modes. MasterCAN DAC converter gets analog signals from vehicle units and digitizes them – frequency signal for RPM measurement, joystick relay voltage indicating boom position, binary signal of ignition key on/off.