Fuel theft prevention on road building machinery

Customer: Vic Florido, entrepreneur (Philippines)

Task: fuel theft prevention on road building machinery

Machinery: excavators, dump trucks, loaders

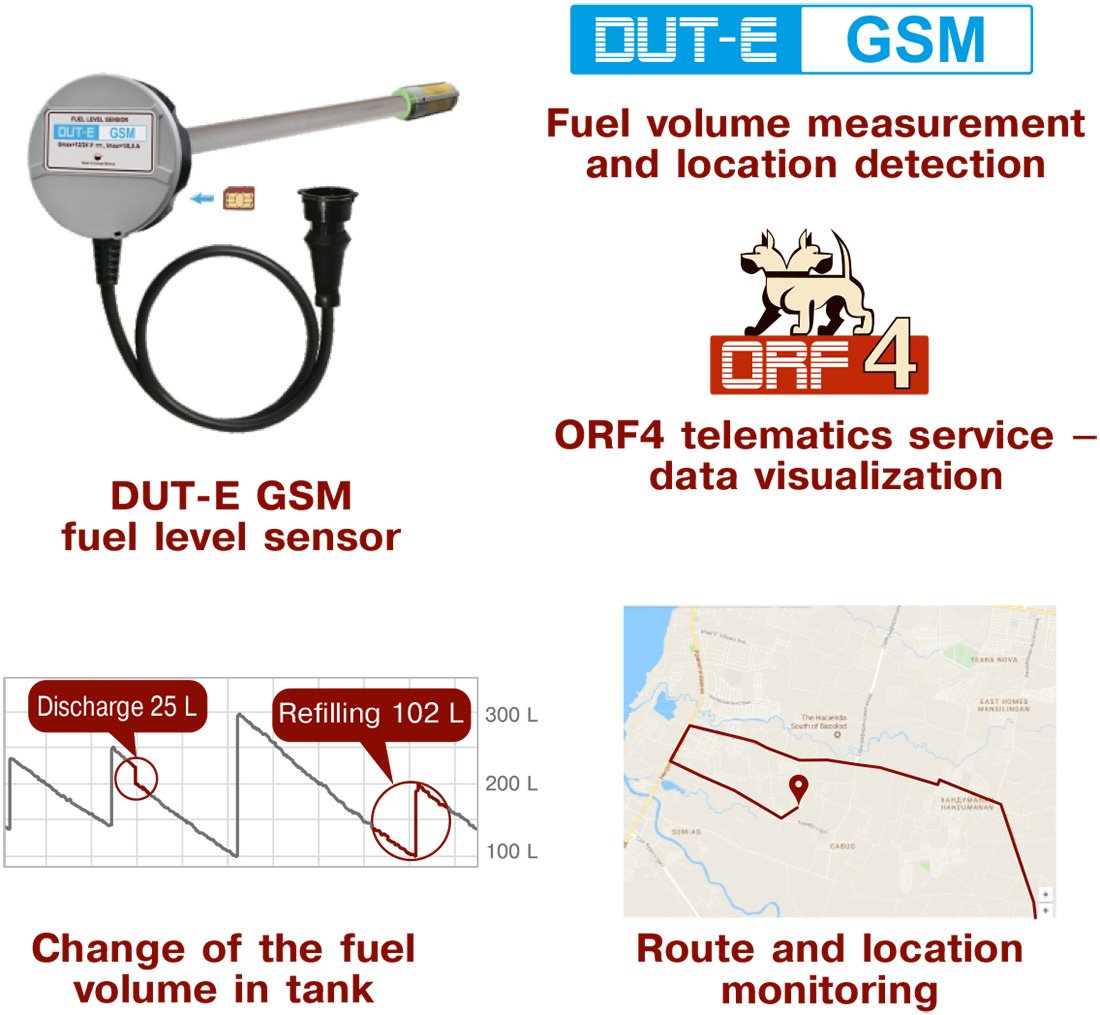

Solution: DUT-E GSM fuel level sensor

Result: 20% fuel economy

The customer

Vic Florido’s field of activity is road building and maintenance.

25 machinery units are used for work:

- excavators and front end loaders – for digging and ground forming works;

- dump trucks – sand, soil and other bulk cargo transportation;

- minibuses – employees transportation.

Works are carried out on the southeast of Negros island (Philippines).

The machinery

Vehicles and road building machinery of Chinese brands are used.

- JAC dump trucks (6х4 wheel configuration, capacity 17 t, engine volume 11,5 L, engine power 375 h.p., fuel tank volume 350 L).

- Sinotruk dump trucks (6х4 wheel configuration, capacity 11 t, engine volume 9,5 L, engine power 250 h.p., fuel tank volume 300 L).

- Lonking front end loaders (capacity 3,5 t, engine volume 6,8 L, engine power 140 h.p., fuel tank volume 250 L).

- Lonking excavators (bucket volume 1,1 m3, engine volume 5,9 L, engine power 150 h.p., fuel tank volume 380 L).

- Hyundai minibuses (engine volume 2,5 L, engine power 120 h.p., fuel tank volume 75 L).

Sinotruck dump trucks

Hyundai minibuses

Lonking front end loaders

JAC dump trucks

Lonking excavators

The task

Fuel theft is common in Philippines. Average salary is less than $270. Cost of diesel fuel is about $0,65 per liter. Fuel drain and further resale became a profitable activity for many drivers, including those who work on customer’s vehicles.

Another problem is ineffective operation of vehicles. It is common for drivers to have long breaks or coming back late from lunch. There is no way to control drivers by personal visits because working sites are far away from each other.

To solve these problems customer contacted Technoton’s regional integrator. The task was to receive various information in real time: vehicle’s location, fuel volume in tank, filling and draining, reports on engine hours and idle time. Solution should be universal for all types of vehicles with no need of complex maintenance.

The solution

For accurate fuel volume, route and location monitoring DUT-E GSM fuel level sensors were mounted on customer’s vehicles.

DUT-E GSM is «two-in-one» device. It combines fuel level sensor with telematics unit. DUT-E GSM is easy to install and it is more resistant to interference than standard «sensor + terminal» combination.

Sensors measure fuel volume in tank with high accuracy (inaccuracy is just 1%). Volumes of filling and draining from tank is measured and reported in real time.

DUT-E GSM detects vehicle’s location and sends following data to fleet operator’s computer:

fuel level in millimeters and fuel volume in liters

information about filling and draining events (precise volume and place of the event)

route and location of vehicles

reports on engine hours and idle time

ORF4 telematics service allows to display vehicle operation data in an easy-to-use form (reports, charts, diagrams).

The main goal of the project – to exclude illegal fuel draining and replacement of fuel with cheaper liquids in a cistern. Third measuring electrode of DUT-E 2Bio detects fuel types by predefined pattern, measures fuel level and volume in each compartment of cistern, and sends alarms on fuel drain/change.

Core features of DUT-E 2Bio:

- possibility of length cutting/extension of measuring tube – savings on delivery to the installation site;

- S6 Technology – easy mounting and configuration, possibility to create a network of several sensors connected to one CAN-port of telematics device.