Axle load sensors

Weight control on air and spring suspension vehicles

Remote cargo weight monitoring

Round-the-clock cargo weight control

Prevention of overload

Detection of overloading in any conditions

Loading-unloading control

Detect cargo events on the map and in automatic reports

Applications

As part of telematics system sensor used to:

prevent overload of the vehicle

define cargo weight

monitore loadings and unloadings

monitore passenger flow

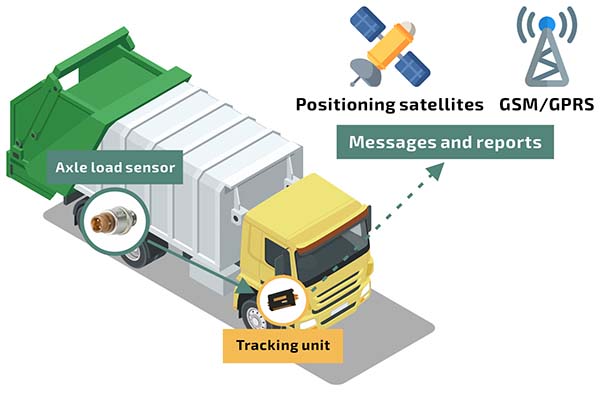

Axle load sensor is designed for axle load control and cargo weight control in vehicle tracking systems. Axle load sensor can be connected to the analog input of tracking device.

With axle load sensor, a vehicle tracking system gets valuable information about the location and time of loading and unloading the vehicle.

Axle load sensor passes the information on raising or lowering the load on axle to terminal . Vehicle tracking system with the help of GPS determines the location and time.

The user of a system receives information about changes in load on axle in the form of parameters or diagrams.

Can be fitted on any vehicle with air or spring suspension

Main features

Universal design – can be fitted on any suspension type

Optimal load – sensor allows maximum vehicle utilization

Passenger and cargo flow – reliable data to perform big-data analysis

Great cost/performance – simple, affordable and durable solution

Can control any weight – sensors work with any types of vehicles and cargo volumes

Different models to fit in any applications

GNOM DDE for air suspension

Pressure sensor GNOM DDE is used to determine the axle load in vehicles equipped with air suspension in transport telematics systems.

Pressure sensor measures the pressure in the vehicle pneumatic system and transmits data as an analog signal to telematics terminal. It is recommended to use online terminals CKPT by Technoton to organize transport tracking with axle load and weight monitoring.

GNOM DP for spring suspension

GNOM DP position sensor is designed for measuring axle and cargo load on vehicles with leaf spring suspension. GNOM DP integrates in a fleet monitoring system and transmits data as an analog signal. The tracking device converts this signal in load mass value according to the calibration table.

GNOM DP position sensor is installed on the rear axle or the rear bogie of the vehicle. A single sensor is enough to monitor vehicle axle and cargo load.