Fuel monitoring in tanker trucks using the DUT-E 2Bio fuel level sensors

Customer: Starcom Systems, Israel

Task: fuel level measurement in cisterns of truck tankers

Machinery: MAN, MB, FAW truck tankers

Result: 60% costs reduction for cargo transportation insurance

Integration partner

Starcom Systems solutions cover various fields – road transportation, container shipping by sea and rail, perishable goods transportation, animal farming, healthcare, banking etc.

150 distributors

50+ countries of operation

15+ years in telematics

Customer’s vehicles

A fleet owner is a shipping company, which has a huge fleet of tanker trucks (or “fuel trucks” – vehicle, which transport fuel from storage to gas stations and other consumers).

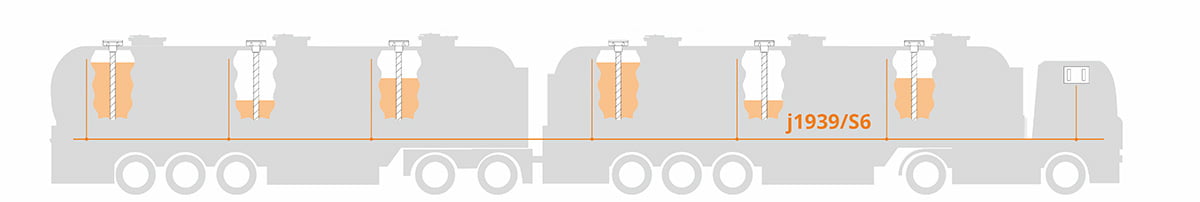

Totally over 1000 truck tankers of various design are involved in fuel transportation: three-axle vehicles with cistern, two-axle freight trucks with three-axle semi-trailer, three-axle vehicles with cistern and a second one on the trailer.

In the same compartment of cistern different fuel types can be transported depending on the day: diesel, gasoline, kerosene.

Fleet’s task

Unfortunately, some roguish drivers steal fuel by discharging high-quality fuel and by adding extraneous liquids to fuel in the tank or fill the tank with various illegal liquids to keep fuel theft hidden.

- Actions like that directly cause loses to fleet owner and entail reputation risks.

- Insurance companies set out so high prices, so that it strongly lowers profitability of transportation.

Fuel tank monitoring allows reducing risks of fuel theft when freighting.

- Telematics system of tanker truck notifies fleet manager on fuel draining and fuel replacement event in cistern in real-time, thus ensuring prompt detection of manipulations with fuel and preventing fuel theft in future.

- So much the more insurance companies are ready to lower prices by several times for vehicles, equipped with fuel tank monitoring system.

Solution

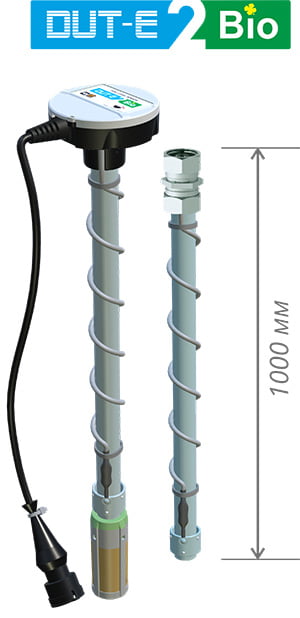

DUT-E 2Bio differential fuel level sensor provides high accuracy of fuel volume measurement no matter what fuel type is. In case fuel tank was filled with gasoline instead of diesel fuel, measurement inaccuracy won’t get higher than 1%. That means, that you don’t have to re-calibrate sensors, make changes to fuel tank table and carry out additional adjustment of the telematics unit anymore. Messages on fuel type/quality change are sent to the tracker, which notifies fleet manager of this Event via e-mail or SMS. The efforts of roguish drivers to steal or change fuel won’t go unnoticed. DUT-E 2Bio fuel sensor is installed in each compartment of a cistern. Adjustment of DUT-E 2Bio probe length takes a few minutes during sensor installation.

All sensors together with Helios Advance tracker are united in a single network with power supply and configuration of hardware from one point. Each sensor has a unique address in the network. This provides an opportunity to see both the total volume of fuel in the fuel tanker and trailer, and also level, volume and temperature of fuel in each compartment.

Differential fuel level sensor and additional section

Core features of DUT-E 2Bio:

- possibility of length cutting/extension of measuring tube – savings on delivery to the installation site;

- S6 Technology – easy mounting and configuration, possibility to create a network of several sensors connected to one CAN-port of telematics device.

Results achieved by Starcom

Totally 2,200 sensors were mounted.

Sensors were mounted over a short period.

Total costs of installation were low thanks to S6 Technology.

The fleet owner decided to continue equipping all new tanker trucks with fuel tank monitoring system based on DUT-E 2Bio fuel level sensors and Helios Advance trackers.

Fleet owner’s benefits from telematics system for fuel trucks:

60% costs reduction for cargo transportation insurance

Fuel drain volume reduction by more than 2 times

excluded illegal fuel change