After fuel monitoring system was installed, the customer started to receive reliable fuel consumption data in real time. Based on information about operation modes (engine speed, temperature) and fuel consumption of every engine, it became possible to define real average fuel consumption, prevent fuel consumption overstatement and cut total fuel costs.

Fuel consumption monitoring of river vessels

DFM CAN flow meters with S6 Technology

Customer: Transmet company

Task: reduction of fuel consumption, preventing fuel misuse

Machinery: dry-cargo ships – vessel engines, diesel generators, boilers

Solution: DFM CAN flow meters with S6 Technology, GPS-trackers

Result: fuel consumption is reduced by 50%

The customer

The company has several directions of operation. One of them is transportation of goods by river. Company owns dry-cargo vessels, such as “Kriushi”, “Kozmodemiansk”, “Ochakov”. Vessels are operated in Volga-Kama river basin and Northern Dvina river basin, also on Ladoga and Onega lakes.

The machinery

Vessels belong to “6th five-year plan, project 576” type: four cargo compartments and a superstructure on stern. Vessel’s length is 94 meters, carrying capacity – 2000 tons, fuel tanks volume – 50 tons, crew – 9 people. Vessels were produced in 1956-1967 in shipyards of USSR and Romania.

Each vessel is equipped with: two engines, left (1) and right (2), main diesel generator (3), auxiliary diesel generator (4) and boiler (5).

The task

Used fuel is accounted using calculation method – ship crew fills in trip statements taking in account approved fuel consumption quotas. Fuel quotas are approved in regulatory documents, which are several years out of date. Fleet owner considered those quotas were too high.

The task was to implement fuel monitoring system that would provide accurate information on instant and total fuel consumption of each engine in real time.

“Kriushi” dry-cargo vessel became the first to be equipped with the fuel monitoring system.

The solution

Fuel monitoring system of diesel units includes 5x DFM fuel flow meters with CAN j1939/S6 interface and 1x Galileosky Glonass/GPS v.5.0. telematics unit. All equipment is operated over S6 Technology.

DFM 250CCAN flow meters are mounted into fuel lines of main engines. DFM 100CCAN are mounted into fuel lines of diesel generators and boiler.

The tracking device receives the following data from fuel flow meters via CAN/S6 interface:

- instant fuel consumption of every engine,

- total fuel consumption of every engine,

- operation time of every engine.

Also, tracking device receives additional data – fuel temperature and engine speed (from tachometer).

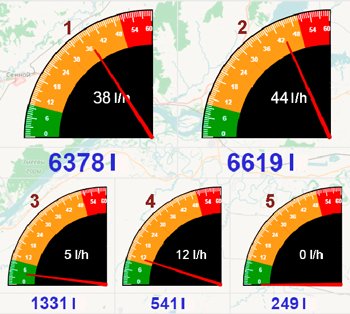

Information from the tracking device is sent to dispatch service’s computer, so they can see ship location and fuel consumption data in real time. All data is available on a virtual dashboard of ORF4 telematics service. Flexible dashboard interface allows to display data in any convenient form: charts, figures, arrow indicators, scales.

Hourly and total fuel consumption:

1) Left engine, 2) Right engine, 3) Main diesel generator, 4) Reserve diesel generator, 5) Boiler

The result

Average total fuel consumption when vessel is moving is about 100 L per hour. This is two times lower than regulatory documentation states. Fuel economy per one machinery hour is 61.50 USD (in June 2017 prices).

Total costs for purchasing and mounting fuel monitoring system paid off twice during the first trip of the vessel.

All costs for equipment and its installation paid off several times on the first trip!

We plan to install fuel consumption monitoring system on “Kozmodemianks” and “Ochakov” dry-cargo vessels and other vessels of our company.”